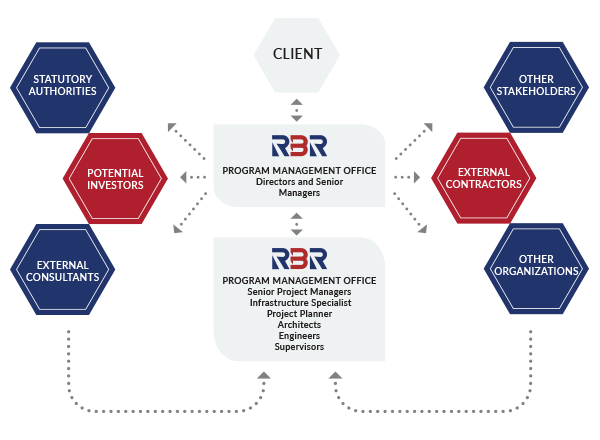

WHO WE ARE

- Global provider of Professional, Technical and Management Support Services to a broad range of markets

- 100 Staff on board and approximately 2500 Experts in Association

- Provide a blend of Global Reach, Local Knowledge, Innovation, and Collaborative Technical Excellence in delivering solutions

- Conveniently located in Singapore to serve International Markets

OUR VISION

ASIA / ASEAN's Number one Project Manage- ment Consultants and Constructors by, 2020

OUR MISSION

Making Construction Projects Stress Free by Adopting Innovative and Best-in Class Engineering & Management Practices

WE VALUE

Clarity in Vision Depth in Knowledge Integrity in Character

Why infrastructure?

- METHODOLOGY

- ADVANTAGES

- OVER VIEW OF CONSTRUCTION PROCESS

- INDUSTRIES SERVED

- STAYING AS A COMPETITIVE EDGE

- PRODUCTS

- PRE-STRESS HOLLOW CORE CONCRETE PANEL

- RBR WALL AND FLOOR BOARDS AND PANELS

- SANDWICH PANEL

- THE PRE-FAB ADVANTAGE

METHODOLOGY

To a in the construction and infrastructure industry, these are extremely desirable attributes when found in its description. ICES are the catalyst that aims to bring about positive changes in today’s construction industry. Our work style ensures that the attributes above do not stay as buzz words on paper but cost effective solutions in practice. As our name suggests, we provide innovative building solutions which are green, clean and effective. We design and manufacture next generation building materials (Magnesium Oxide or BESTATM boards, ALC, High Frequency Welded Steel Columns & Beams etc…) and pre- fabricated building Systems to address the growing demand for fast, efficient and sustainable construction methodology. With exposure to the best in class techniques and materials across the breadth of Asia and the strongest convictions that the construction industry can leverage on the latest processes, technologies and materials available the world over ,we are a company that believes in delivering on our promises.

ADVANTAGES

- Fast and dry condition.

- Less man hours for the total construction method

- Minimum use of natural resources like formworks cements and reinforced concrete.

- Steel structures have high structural flexibility to accommodate earthquakes and hurricanes.

- Minimum hoisting, heavy equipment’s and site welding are required.

- All materials are pre-manufactured in the factories, facilitating the site installation under most of the weather conditions.

- Masonry look-like houses.

OVER VIEW OF CONSTRUCTION PROCESS

- Prepare of civil & foundation at site as according to design requirement.

- Installation of Steel structure as according to site condition equipment’s availability and comply with drawings given.

- After pre-assemble of all steel structure, ensure properly & correctly secure the structure in position & alignment.

- After properly tightening of foundation bolts between the foundation & column’s base plate, grouting the base the plate & casting of the Ground Floor concrete slab.

- Installation of pre-stress concrete plank for ground and all upper floors.

- Installation of galvanize steel truss & Roofing system.

- Installation of Light weight concrete panel for External & Internal wall.

- Installation of Magnesium fire resistance board for all columns and beams.

- Installation of ceiling.

- Installation of standard Window & Door.

- Apply Skin Coat on the external & internal wall.

- External & Internal wall painting & Tiling.

INDUSTRIES SERVED

- Commercial.

- Education Government.

- Smart City Development.

- Hospitality.

- Infrastructure.

- Residential.

- Technology.

STAYING AS A COMPETITIVE EDGE

As the costs of construction trend upward not withstanding economic indicators pointing to lower demand and market prices. It has become increasing tough for Owners and developers to stay ahead of Economic parameters and curves. The technology that we are using, though environmentally friendly and in line with sustainability, is not new and in fact it has been widely used in Asia, Australia, New Zealand and various regional markets. We set ourselves apart through Value Engineering which we believe gives Owners and Developers the best combination of methodologies available to the Construction Sector today.

PRODUCTS

High Frequency Welded (HFW) Light Gauge Beams High Frequency Welding also referred to as Fusion Welding is the class to which the Electron Beam Welding process belongs used to produce Light Gauge steel Beams. In electron beam welding (EBW) a beam of high-velocity electrons is applied to the materials being joined. The work pieces along with the filler metal, if used, melt as the kinetic energy of the electrons is transformed into heat upon impact, to form part of the weld. The welding is often done in conditions of a vacuum to prevent dispersion of the electron beam. The three primary methods of EBW are each applied in different welding environments. Vacuum welding low pressure welding in air welding.

PRE-STRESS HOLLOW CORE CONCRETE PANEL

To a project in the construction and infrastructure industry, these are extremely desirable attributes when found in its description. ICES are the catalyst that aims to bring about positive changes in today’s construction industry. Our work style ensures that the attributes above do not stay as buzz words on paper but cost effective solutions in practice. As our name suggests, we provide innovative building solutions which are green, clean and effective. We design and manufacture next generation building materials (Magnesium Oxide or BESTATM boards, ALC, High Frequency Welded Steel Columns & Beams etc…) and pre- fabricated building Systems to address the growing demand for fast, efficient and sustainable construction methodology. With exposure to the best in class techniques and materials across the breadth of Asia and the strongest convictions that the construction industry can leverage on the latest processes, technologies and materials available the world over ,we are a company that believes in delivering on our promises.

RBR WALL AND FLOOR BOARDS AND PANELS

Magnesium oxide, with a melting point of 2800 centigrade is often used as a basic refractory material for lining crucibles and furnaces. Its versatility has seen to it being used often in commercial and residential constructions. In addition to general building board users, Magnesium oxide has a higher fire rating, resistance to moulds and mildew and is relatively sound proof. A relatively new inorganic bonded composite, MgO boards are produced using in alkali-resistant fibre-glass mesh as a strengthening material. Magnesium oxide derives its strength from the oxide bond. It is often used as a new age substitute for the traditional gypsum drywall, ceiling cover material or as sheathing. Magnesium oxide also finds use in construction applications like fascias, soffits, shaft-liner & area separation wall sheathing, and as tile backing (backer board) or substrates for coatings and insulated systems. Available in various sizes and thickness, Magnesium oxide boards are classified as a non- paper cover material. Magnesium oxide boards are widely used in Asia as the primary construction material. It was designated as the ‘official; construction specified material of the 2008 Summer Olympic Games. It was used extensively on the inside and outside of the walls, fireproofing beams and as the sub-floor sheathing in what was once the world’s tallest building the Taipei 101.

SANDWICH PANEL

RBR Sandwich panel is a kind of new and superior non-combustible construction material with numerous applications in commercial and residential projects of all kinds. It is a kind of revolutionary product which changes the way of traditional dry wall construction. It can save two third construction times, reduce 50 % of the total weight and save 30%-40% of the total construction cost. It provides a hard, long lasting surface that look and feel like hard cement plastering but is fireproof and resistant to damage from water, humidity, freezing, organisms, chlorine, salt and more. Excellent material for fireproof and sound proofing applications. The ideal wall panel for pool buildings, garages, kitchen and wet areas or any of the more demanding locations in buildings. RBR sandwich panel is developed from the dry wall construction; it is made of RBR board at both faces, heat and sound insulation materials as infill, and tongue & groove as joint. It is a complete sandwich wall panel which can be used directly as the wall without any metal stud & track, nor plastering. It moves the complex work at the site of workshop. Well & Able established the standard work flow at workshop to make the complex work easier and have more guarantee on the quality. Therefore, RBR Sandwich Panel is also a kind of prefab wall panel.

THE PRE-FAB ADVANTAGE

- Green and Clean Construction.

- Ecological and Sustainable Construction.

- Minimum Pollution (Noise & Debris) and Disturbances.